When constructing or reconstructing a low-volume road, local engineers in Minnesota are faced with a dilemma: Choose a polymer-modified binder (PMB) asphalt that will be more expensive upfront but extend the road’s life, or go with an unmodified binder that will cost less initially but may not last as long?

A project sponsored by the Minnesota Local Road Research Board provides clarity. U of M researchers found that modified binders are more cost-effective in the long run, even for low-volume roads.

Used in the US for many decades, PMBs decrease rutting, fatigue cracking, and low-temperature cracking. The performance benefits are clear—longer intervals before maintenance is needed—and many local agencies already use PMBs in new road construction. However, the few studies of their cost-effectiveness for low-volume roads had mixed results, says Mihai Marasteanu, a professor with the Department of Civil, Environmental and Geo- Engineering and the project’s principal investigator.

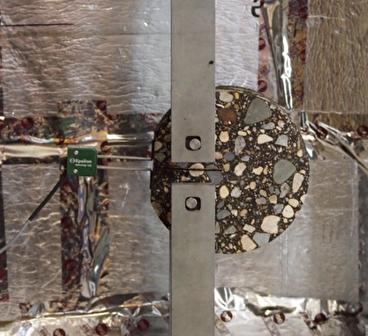

Researchers studied the differences between modified and unmodified asphalt mixtures in Minnesota using a variety of methods, including a review of previous research and case studies, analysis of historical road data, and laboratory testing of road samples.

A life-cycle cost comparison of the construction costs for modified versus unmodified asphalt pavements found that using PMBs in new construction could extend the life of a low-volume road in Minnesota by six years, resulting in a 14 percent savings. The estimate does not include road-user cost savings from decreased maintenance time.

“This research confirmed the benefits of polymer-modified binders we’ve been hearing about,” says Jed Nordin, the Hubbard County Highway Department’s engineer/public works coordinator. “The extra costs are likely justified, even on lower-traffic roads, due to the longer life cycle of a road paved with these binders.”

The project can also provide insight into other life-cycle cost calculations. “The step-by-step process we developed for performing a life-cycle cost analysis can be applied in other contexts,” Marasteanu says.

—Megan Tsai, contributing writer